Everything depends on quality

Today, windows are expected to perform a variety of functions. Since the performance of a window is mainly determined by the window profiles, the profile quality is therefore important. The most important standard for plastic profiles sets various performance requirements and distinguishes between different classes according to the wall thickness of the profiles: A, B and C. VEKA produces only quality profiles of class A, which are particularly efficient with their thick walls. This high quality is subject to very close and strict control.

Table of contents

- Windows have to do a lot

- What exactly is quality?

- The wall thickness as an important feature

- Class A means stronger windows

- You can rely on VEKA quality

Windows have to do a lot

Allowing daylight into the building and, if necessary, ventilation: these were the main requirements for windows in the past. Today, building owners have every right to expect more. This starts with protection against wind and weather. Modern windows should remain reliably tight even in gale-force winds and driving rain, thus guaranteeing comfort even under adverse conditions.

But what is almost more important is that efficient windows should keep valuable heat in the building as well as possible, so that the climate and at the same time the wallet are protected. In addition, they should protect against summer heat and offer burglars so much resistance that, at best, they are unnerved and run for the hills. And of course, they should be easy to operate and retain their beautiful appearance for many years.

What exactly is quality?

From the point of view of a builder or a real estate user, probably in general, a window that combines all the above performance characteristics could be called a quality window. In principle, such windows can be made of various materials, but plastic windows offer two important advantages: On the one hand, they are significantly cheaper than aluminum windows, for example, and on the other hand, they are much easier to maintain than wooden windows.

Professionals have a much more precise idea of what is a quality window. This is because a large number of national and international standards exist for windows and also for doors. They describe down to the smallest detail which properties windows as finished building products and even the window profiles and glass panes from which they are made must have. For example, the air permeability of windows is dealt with in a separate DIN standard, as is the driving rain resistance or the impact resistance of plastic profiles. As if that were not enough, the measurement methods used to check compliance with the various characteristics are also standardized.

The wall thickness as an important feature

Ultimately, almost all performance characteristics of a window depend directly or indirectly on the window profile . The European standard DIN EN 12608 is therefore particularly important for the question of the quality of a vinyl window, because it deals in detail with the requirements for window and door profiles made of rigid PVC, with the relevant test methods and also with classification. A separate section is devoted to the thickness of the profile walls as the decisive characteristic for classification.

The focus here is on the outer walls of the profile. On the one hand, these are the visible surfaces, i.e. the vertical outer surfaces of the profile facing the inside of the building or the surroundings. On the other hand, there are the horizontal outer surfaces that face the rebate or the building connection and are not visible when the window is closed. The interaction of these surfaces is critical to the structural integrity of the profile: It ensures that warping or deformation of the profile does not occur, thus guaranteeing long-term serviceability.

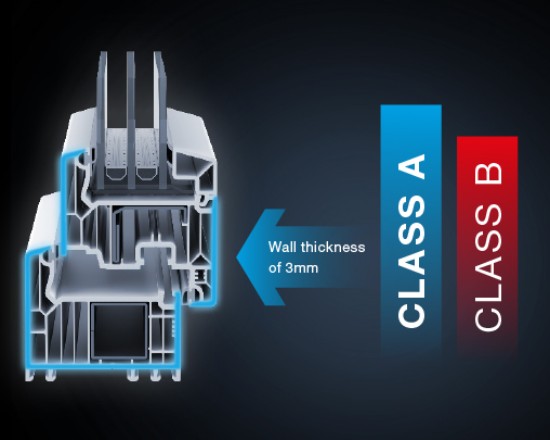

The standard defines three classes: A, B and C. Class C window profiles do not have to meet minimum wall thickness requirements. For class B profiles, the walls of the visible surfaces must be at least 2.5 mm thick, and the walls in the rebate and connection area must be at least 2.0 mm thick. The highest requirements are placed on class A profiles: Here, the wall thickness of the visible surfaces must be at least 2.8 mm, and at least 2.5 mm is required in the rebate and connection area.

Class A means stronger windows

VEKA is the only manufacturer in Germany that exclusively produces plastic profile systems in Class A quality. Window profiles from VEKA have wall thicknesses of 3.0 mm on the visible surfaces and 2.7 mm in the rebate and connection area (tolerance 0.2 mm in each case). Compared to class B profiles, this means at least 10 or 20 % thicker profile walls. To achieve these particularly high wall thicknesses, around 14% more material is used in profile production. Does this additional effort pay off? The figures speak for themselves!

Class A quality profiles are particularly stable and can withstand higher mechanical loads. This has been shown in elaborate series of tests conducted by VEKA in its test laboratory. The measurements showed that windows made of class A profiles have a 15-20% higher corner strength than those made of class B profiles. They also bend 10-12% less under load. And up to 20 % more force is required to tear out screw connections with class A profiles than with lower-quality profiles.

If these measurement results are transferred to the desired performance of a window, the advantage of class A profiles in accordance with DIN EN 12608 becomes even clearer. More corner strength, less deflection and tighter-fitting screw connections of all fittings mean that windows made from such high-quality profiles can better support heavy functional glazing. Even with large-area elements, this ensures effortless ease of use. What's more, windows made from class A profiles also keep reliably tight during storms. And finally, they make it more difficult for burglars to get in, so the higher quality also means better protection for your own belongings.

You can rely on VEKA quality

Wall thickness is therefore a key factor in the quality of a window profile - and ultimately in the performance and durability of the installed window. It is literally the inner values that matter. However, this also means that the major differences in the quality of windows and doors can hardly be seen from the outside, even for experts.

With windows and doors made of class A profiles from VEKA, building owners can always be sure that they are choosing the highest quality. Due to their special performance and durability, such windows and doors enhance any property for decades, in new construction as well as in modernization.

As the world's leading system provider with a success story spanning more than 50 years, VEKA consistently adheres to this outstanding quality. To safeguard it, the company has established a system of close-meshed quality controls. These controls extend along the entire production chain - from the careful inspection of the raw materials delivered to the precise mixing of the company's own compound formulation to the measurement of the extruded profiles. The checks are more stringent, take place at shorter intervals and at more measuring points than required by the renowned RAL quality assurance system. All these measures serve one goal: to provide building owners with the best quality for the realization of their living dreams.

Strict. Stricter. VEKA!

Quality is not an end in itself, but a promise to all building owners. That is why VEKA tests more strictly and more closely than required.

VEKA

Number of measuring points: 20

Tolerance profile height: 0.3 mm

Tolerance profile depth: 0.2 mm

Test cycle: 2 h

RAL

Number of measuring points: 5

Tolerance profile height: 0.5 mm

Tolerance profile depth: 0.3 mm

Test cycle: 4 h

Do you have any questions?

If you have any questions about "windows and doors", please feel free to send us an e-mail. Or contact your local VEKA partner directly - they will be happy to advise you in detail at the designated specialist company!